Trick Benefits of Using a Membrane Switch in Industrial Applications

Trick Benefits of Using a Membrane Switch in Industrial Applications

Blog Article

Just How Membrane Layer Changes Add To the Sturdiness of Electronic Control Panels

Membrane layer switches play a crucial function in improving the toughness of electronic control panels, mostly via their multi-layered building which supplies reliable defense against environmental variables such as wetness and dust. This design not just minimizes the danger of circuit damages and rust however likewise promotes ease of upkeep due to its seamless surface. The absence of moving parts substantially decreases the possibility of mechanical failures, making membrane changes ideal for demanding applications. The ramifications of these features extend past plain protection, increasing questions about their more comprehensive influence on capability and customer experience.

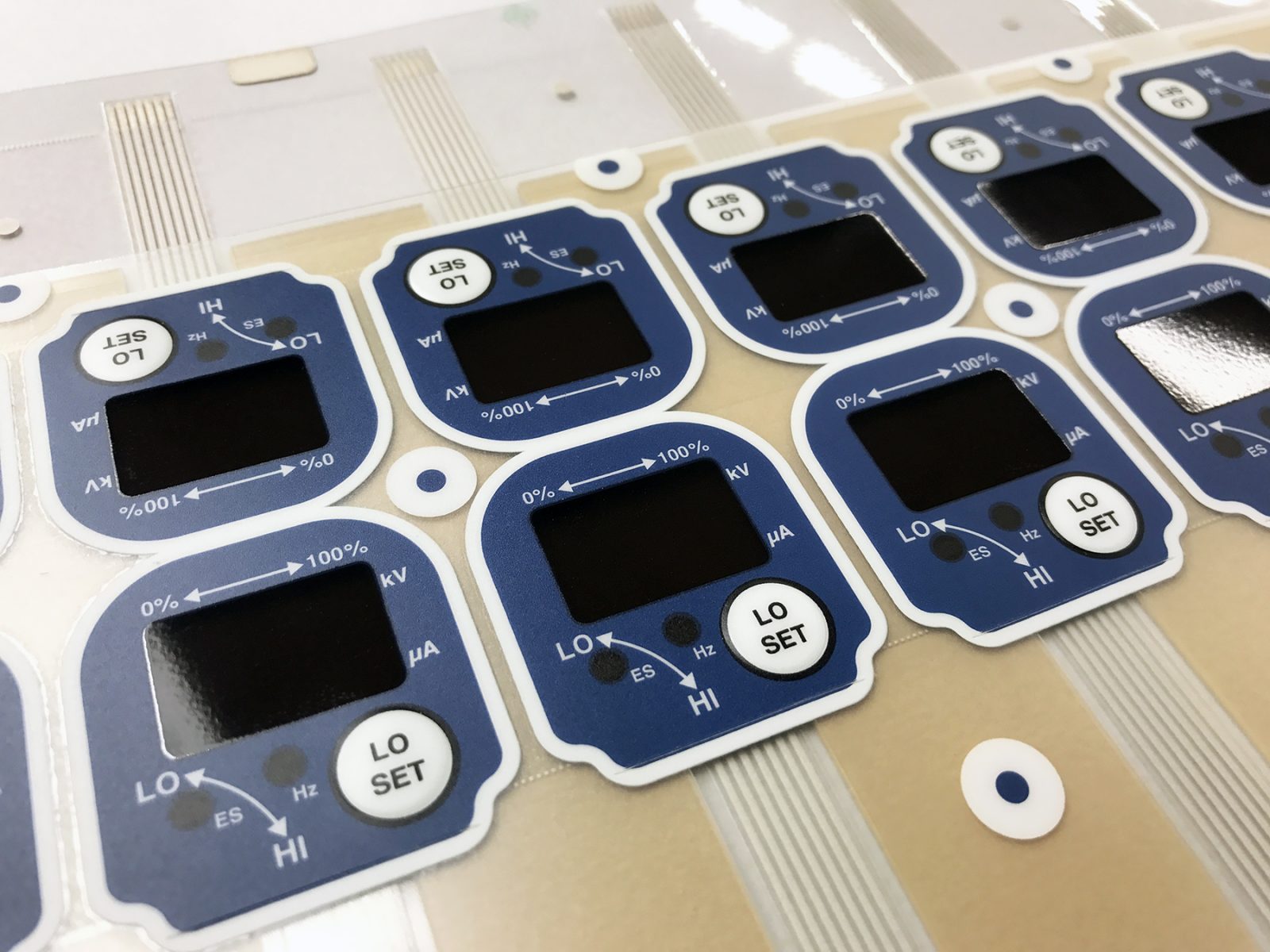

Meaning of Membrane Switches

Membrane layer buttons are developed to be slim and light-weight, making them ideal for applications where space is restricted. They can be made in various shapes, dimensions, and shades, supplying adaptability in style that meets visual and functional needs. Additionally, membrane layer buttons can integrate various innovations, such as tactile feedback and LED indicators, improving individual experience.

As a result of their construction, membrane buttons are usually resistant to dust, moisture, and basic wear, adding to their resilience sought after environments. Their seamless layout not just helps with easy cleansing but additionally decreases the risk of mechanical failure, making them a favored selection for producers looking for reliable individual interfaces in their electronic control board.

Defense Against Environmental Elements

The style of membrane layer changes inherently gives a level of protection versus different ecological variables, which is vital for keeping capability in tough problems - Membrane Switch. These buttons are commonly constructed with layers of adaptable materials that shield internal elements from wetness, dirt, and impurities. By enveloping the circuitry, membrane layer switches minimize the danger of brief circuits and corrosion, which can substantially impair efficiency

In addition, the use of robust adhesives and sealants throughout production enhances their resistance to environmental challenges. Membrane layer switches can endure exposure to chemicals and solvents, making them suitable for industries such as food processing and health care, where hygiene and sanitation are extremely important. Their seamless surface style additionally avoids the accumulation of dirt and microorganisms, helping with simpler cleansing and maintenance.

Temperature level changes are one more environmental concern, and membrane switches are engineered to operate successfully throughout a variety of temperatures (Membrane Switch). This versatility makes certain that control board remain operational in various settings, from commercial settings to customer electronics

Influence on User Interaction

User interaction with electronic control board is substantially affected by the style and functionality of membrane buttons. These switches provide a tactile user interface that boosts the general customer experience, permitting for instinctive navigation and control. Their responsive nature ensures that individuals get immediate responses upon activation, which is crucial for jobs requiring precision and performance.

Moreover, the smooth surface of membrane layer switches over assists in easy cleansing and maintenance, advertising customer self-confidence in the dependability of the interface. This cleanliness is especially essential in settings where health is extremely important, such as clinical or food processing setups. Furthermore, the small and lightweight design of membrane layer changes adds to the visual charm of control board, encouraging individual involvement through a contemporary and sleek look.

Furthermore, the assimilation of aesthetic aspects, such as published symbols and backlighting, aids users rapidly identify functions, minimizing the learning contour connected with new tools. Consequently, customers can operate tools much more successfully, causing enhanced efficiency and fulfillment. In recap, membrane switches play a pivotal function in boosting individual communication by read the full info here incorporating performance, looks, and ease of use, ultimately resulting in enhanced functional efficiency.

Layout Flexibility and Customization

Style versatility and personalization are essential elements of membrane layer switches, making it possible for producers to tailor electronic control board to specific applications and customer requirements. This versatility enables the integration of numerous layout elements, such as colors, graphics, and structures, which can enhance the aesthetic appeal and user engagement of the control panel.

Membrane layer buttons can be customized in dimension and form, accommodating a vast array of tools and applications, from commercial equipment to customer electronic devices. This adaptability makes sure that producers can develop intuitive interfaces that line up with customer assumptions and functional requirements. Furthermore, the ability to sites integrate special attributes such as backlighting or tactile feedback better enhances use, enabling a more interactive experience.

Furthermore, the production procedure for membrane layer changes sustains the quick prototyping of layouts, enabling manufacturers to iterate and fine-tune their principles rapidly. This capability not just speeds up the growth timeline but also guarantees that the final product satisfies specific practical and aesthetic requirements.

Cost-Effectiveness and Long Life

Cost-effectiveness and long life are considerable benefits of membrane switches, making them an attractive option for manufacturers and end-users alike. These buttons are usually cheaper to create than conventional mechanical switches, primarily due to their simplified manufacturing procedures and the minimized number of components called for. This price benefit extends not only to first manufacturing however also to lasting operational expenditures, as membrane switches usually call for less maintenance and have a reduced failing rate.

Moreover, the durability of membrane switches over adds to their general worth. Built from resilient products, they are resistant to ecological factors such as dampness, dust, and chemicals, which can lead to early wear in other button types. The lack of relocating parts look at here now decreases mechanical failure, allowing membrane switches to preserve performance over expanded periods.

This resilience is specifically helpful in applications requiring consistent performance under requiring conditions, such as medical tools and industrial devices. Ultimately, the combination of cost-effectiveness and long life makes membrane changes a financially viable option for suppliers, providing trusted services that hold up against the test of time while enhancing financial factors to consider.

Verdict

In final thought, membrane buttons dramatically boost the durability of electronic control panels via their durable building and safety functions - Membrane Switch. Generally, membrane switches over represent a dependable and cost-efficient selection for boosting the durability and performance of electronic control systems.

Report this page